Methods

A year or so ago I had some sign carving to do and there was a bit I couldn't reach so I made this little chisel chap out of a snapped driver bit. He works like a charm and I use him for a lot of other inaccessible stuff now. I am right handed, so my left thumb acts as a stop here, the right hand would be swinging through an arc of 80 degrees or so scorping out a sliver each time, either in the same spot to make a deep hollow, or moving along to a new spot. For really tight spots or if the thumb starts to bleat too loudly you can make up little sticks to act as stoppers. As you can imagine, the leverage afforded by the handle means you don't have to put much effort into cutting. Unfortunately this is not one of those Harry potter moving pictures, so there is no motion, neither can you hear the lovely scorping sound or get that christmas tree scent.

A year or so ago I had some sign carving to do and there was a bit I couldn't reach so I made this little chisel chap out of a snapped driver bit. He works like a charm and I use him for a lot of other inaccessible stuff now. I am right handed, so my left thumb acts as a stop here, the right hand would be swinging through an arc of 80 degrees or so scorping out a sliver each time, either in the same spot to make a deep hollow, or moving along to a new spot. For really tight spots or if the thumb starts to bleat too loudly you can make up little sticks to act as stoppers. As you can imagine, the leverage afforded by the handle means you don't have to put much effort into cutting. Unfortunately this is not one of those Harry potter moving pictures, so there is no motion, neither can you hear the lovely scorping sound or get that christmas tree scent.You don't need much gear to make something similar. I had a propane torch a few fire bricks, a pair of mole grips, a little hammer and a piece of scrap iron with a curve ground into it to act as a swage. When you have done beating the steel about you heat it up to where a magnet just stops sticking to it and then dunk it into water. This leaves the tool steel hard and I just left it that way with no tempering. I am careful not to over stress it. But the reason for risking destruction is that it is such a tiny little poppet that I want it to keep its edge, because it is a bugger to sharpen and there isn't a lot of blade length to assure it a long life. The inside curve is the problem area, actually you need a few sharpening stones as well while you are out shopping for mole grips....

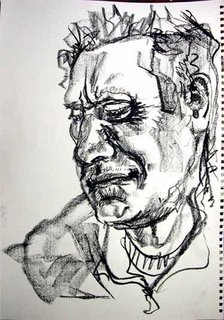

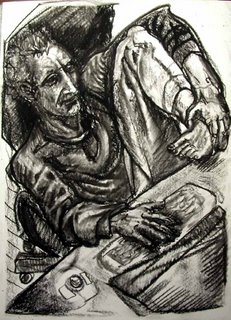

Compressed charcoal on cartridge 29x42cm